- #Contact preform formlabs upgrade

- #Contact preform formlabs software

- #Contact preform formlabs plus

- #Contact preform formlabs series

#Contact preform formlabs software

The upgraded version of the software comes with a host of improvements that include a streamlined user interface and direct integration with the FormLabs support site.

#Contact preform formlabs upgrade

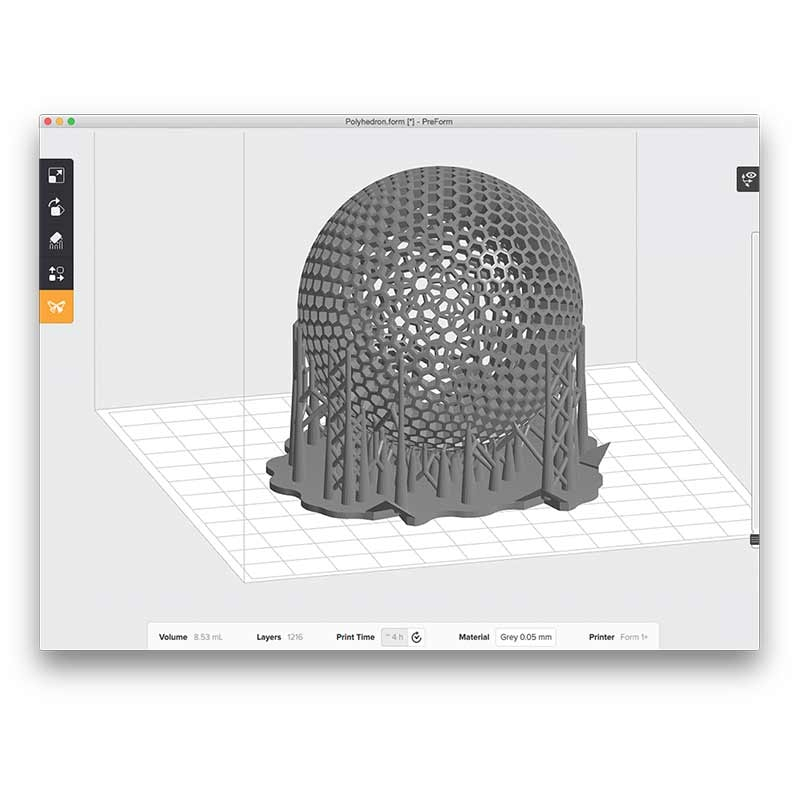

Looking for biocompatible materials? Learn more about the large format dental and medical 3D printer, the Form 3B+.FormLabs has announced the release of PreForm 1.6, the latest upgrade to the 3D printing software that powers the highly regarded Form1+ 3D Printer. In addition, Formlabs systems are known for their smooth finish, something that will enthuse even Model making Model making on 1/32 or even 1/220 scale format? The Form 3+ can handle it! With a resolution of 25 microns, few models are too small for the Form 3+. The versatility of the Form 3+ on the production floor is almost limitless!

From cable clips or part positioning to even "short run" injection molds. Means of Production With its high accuracy and durable materials, the Form 3+ is the ideal addition to any production line.

#Contact preform formlabs series

Production technique for small and medium-sized series of products.

With the materials from Formlabs, it is therefore possible to consider the use of SLA technology as a fully-fledged With the (LFS™) SLA technique, thin-walled injection molded parts can be printed with the great ease, making in-house iteration has never been this fast.Įnd-use parts Formlabs engineering materials are specially formulated for specific mechanical properties that last. From soft rubber-like materials to very rigid glass-filled Due to the wide range of materials in the Formlabs ecosystem, almost any common material can be simulated. These “light touch” support attachments break easily and leave minimal traces on the printed part.Īpplications Prototyping With the Form 3+ you can create very accurate prototypes with the greatest of ease. The ease with which materials can be changed on the Form 3+ means you get more out of your printing system.īreak away support Due to the increased laser strength combined with the light filter, support attachments can be printed very fine. In addition, scaling upĪnd managing SLA production has never been easier with the online Formlabs Dashboard.Įasy to change materials Switch from a rigid to a soft material in an instant. Placement, orientation and support placement literally with the push of a button. Preform and Dashboard Software With Preform, complex 3D models are converted into printable files with the greatest of ease.

The LFS™ technology combined with adaptive layer technology ensures a very high production speed Including:Įigenschappen LFS™ technology The Formlabs LFS™ technology ensures a very high surface quality, even with very flexible materials. Please contact us if you have a question.Īutomate your workflow An new addition to the Formlabs assortment is the Form Auto, a hardware extension for the Form 3+ and Form 3B+ Series 3D printers that automatically removes finished parts with the Quick-Release Technology Build Platform 2 and starts the next print without the need for operator interaction, enabling 24/7 3D printing with no printer downtime.

#Contact preform formlabs plus

To confirm, lookįor a plus sign in the lower left corner of the sticker on the back of your printer. With Preform Dashboard, the form 3+ can be easily managed and multiple systems can be combined to increase total print capacity from prototyping to production.ĭo you own a Form 3? You may be able to upgrade it to the Form 3+. With the user-friendly software Preform, CAD models can easily be converted Consistently produce high-quality prototypes and end-use parts with the Form 3+ SLA printer. The Form 3+ offers fast print speeds and accuracy combined with a wide range of materials.

0 kommentar(er)

0 kommentar(er)